6-Axis CNC Robotic Milling for a more efficient secondary rotational molding process

Material removal and cutting out features in your plastic components is safer, faster, and more consistent with the help of RoboMill

BENEFITS:

Increased Operator Safety

Reduce physical strain from dangerous, difficult, and dirty tasks

Reduce repetitive motion injuries

Solid polycarbonate panels keeps the operator out of harm’s way

Increased Quality

Robotic milling ensures accurate and consistent tool paths every time

Increased Productivity

Ability to Load and Unload Parts while the Robot is Milling will increase throughput

Reduced Scrap

The iRVision system ensures proper set-ups

The iRVision helps makes adjustments to compensate for material variations

Clean up is a breeze with built in anti-static and vacuum systems inside and outside of the enclosure

KEY FEATURES

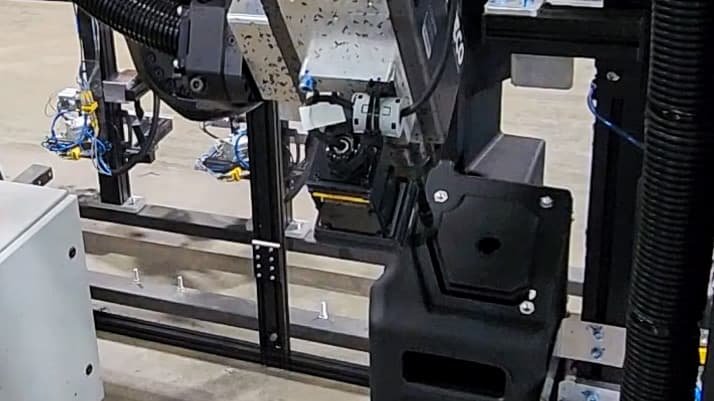

Fanuc M-20iD/25 6-axis Robot with Teach Pendant and Controller

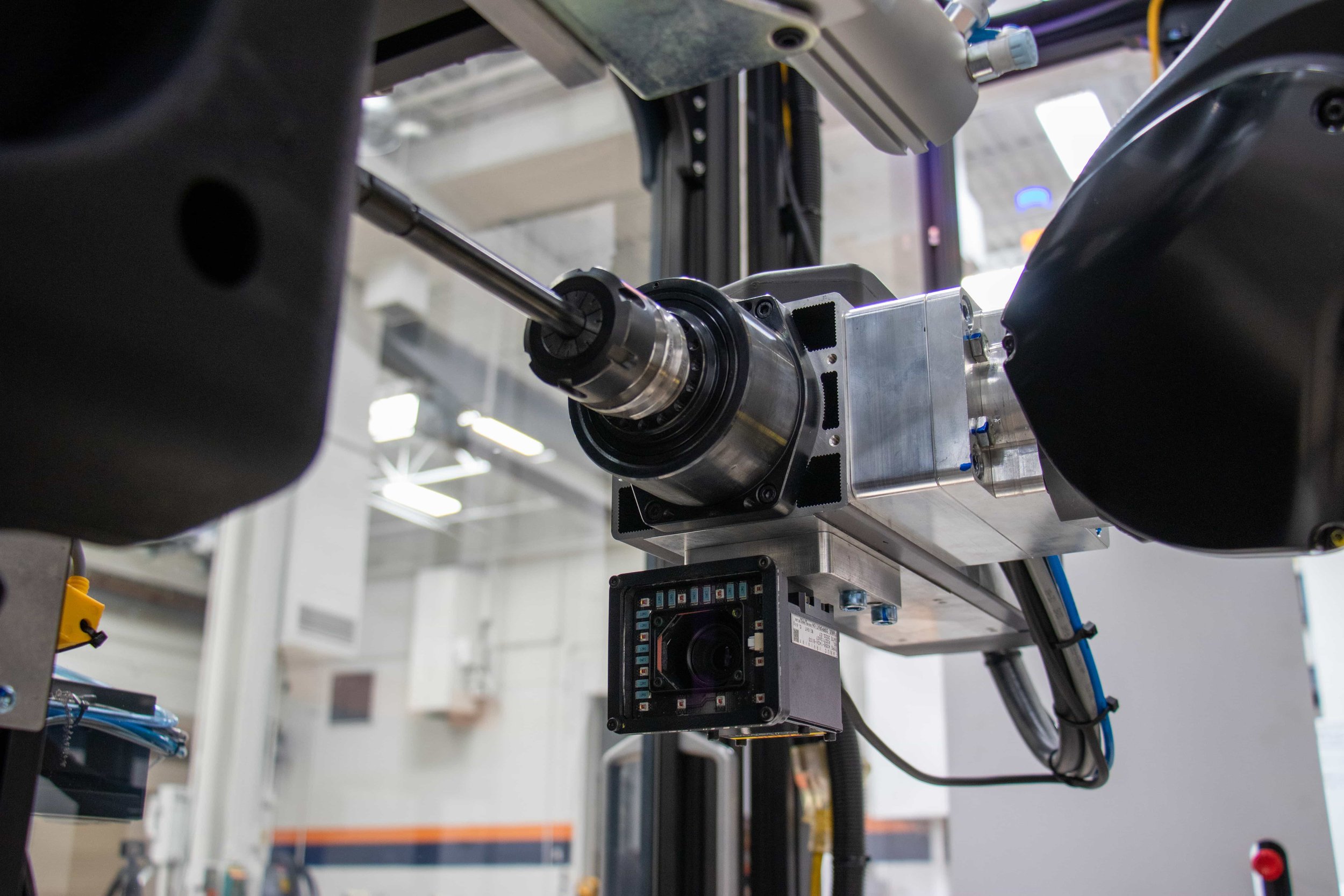

Fanuc iRVision System

Part Fixture Verification

Program Adjustments Based on Part Variations

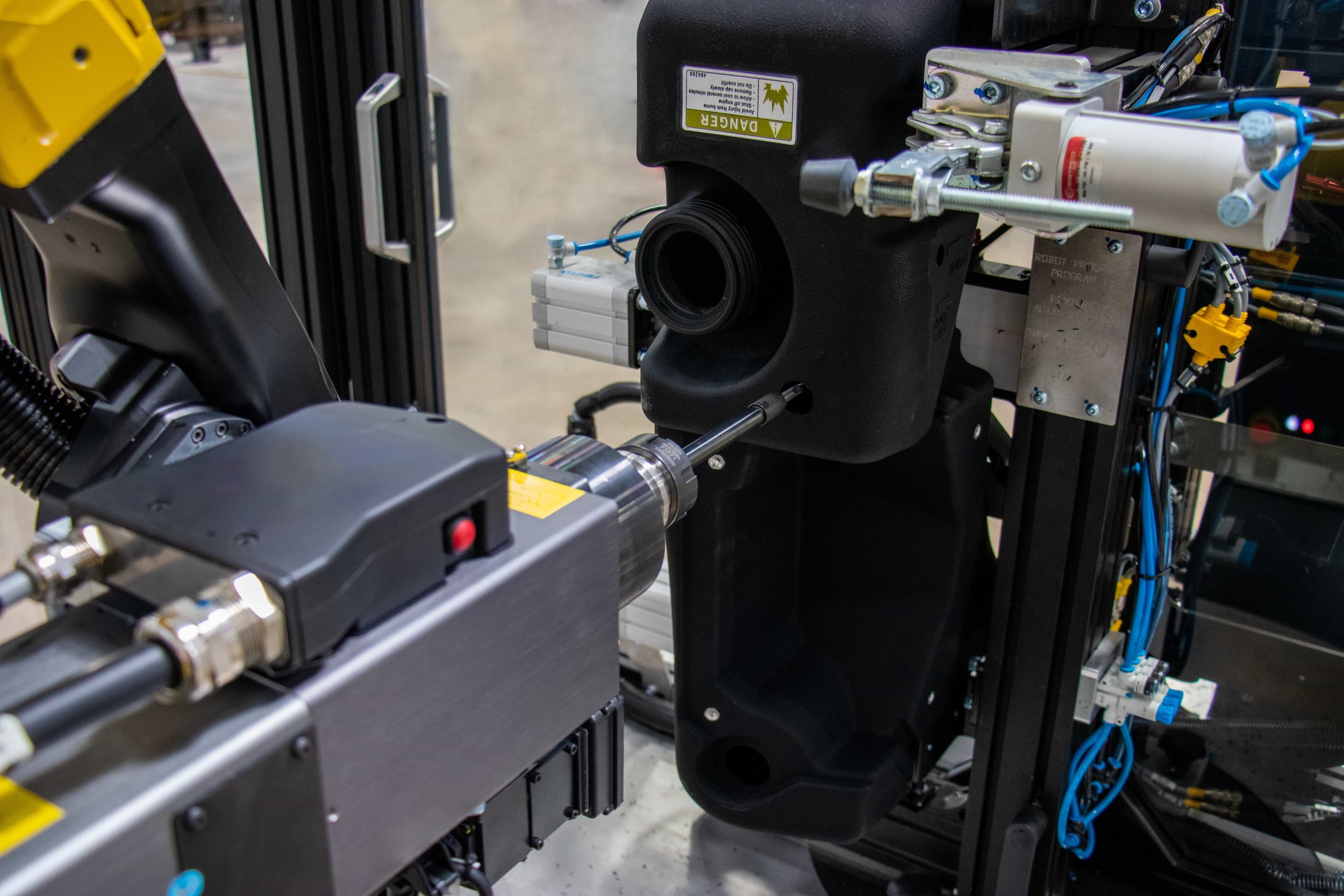

Single Spindle with Automatic Tool Changer

Max power: 4/4.5 kW

Nominal rpm: 12,000

Maximum rpm: 24,000

Max torque: 3.2/3.6 Nm

Tool taper: ISO30

Electric fan cooled

Ceramic bearings (grease lubrication for life)

6-position Tool Storage Enclosure

Tool Breakage Monitoring

Tool Calibration System

Manual Turn Table for Two Fixtures

Quick Change Fixture Pneumatic and Electronic System

Central Vacuum System

Internal Floor Sweep

External Retractable Hose (Hide-A-Hose)

Anti-Static Blower System

Polycarbonate Panel Enclosure

Air Pressure Regulator and Monitor with Shut Off and Dump Valves

System Controls

IGNITE A BOLD TRANSFORMATION IN YOUR WORKPLACE WITH AUTOMATED MILLING

To learn how Metalcraft Automation Group can improve your manufacturing processes, contact us today!