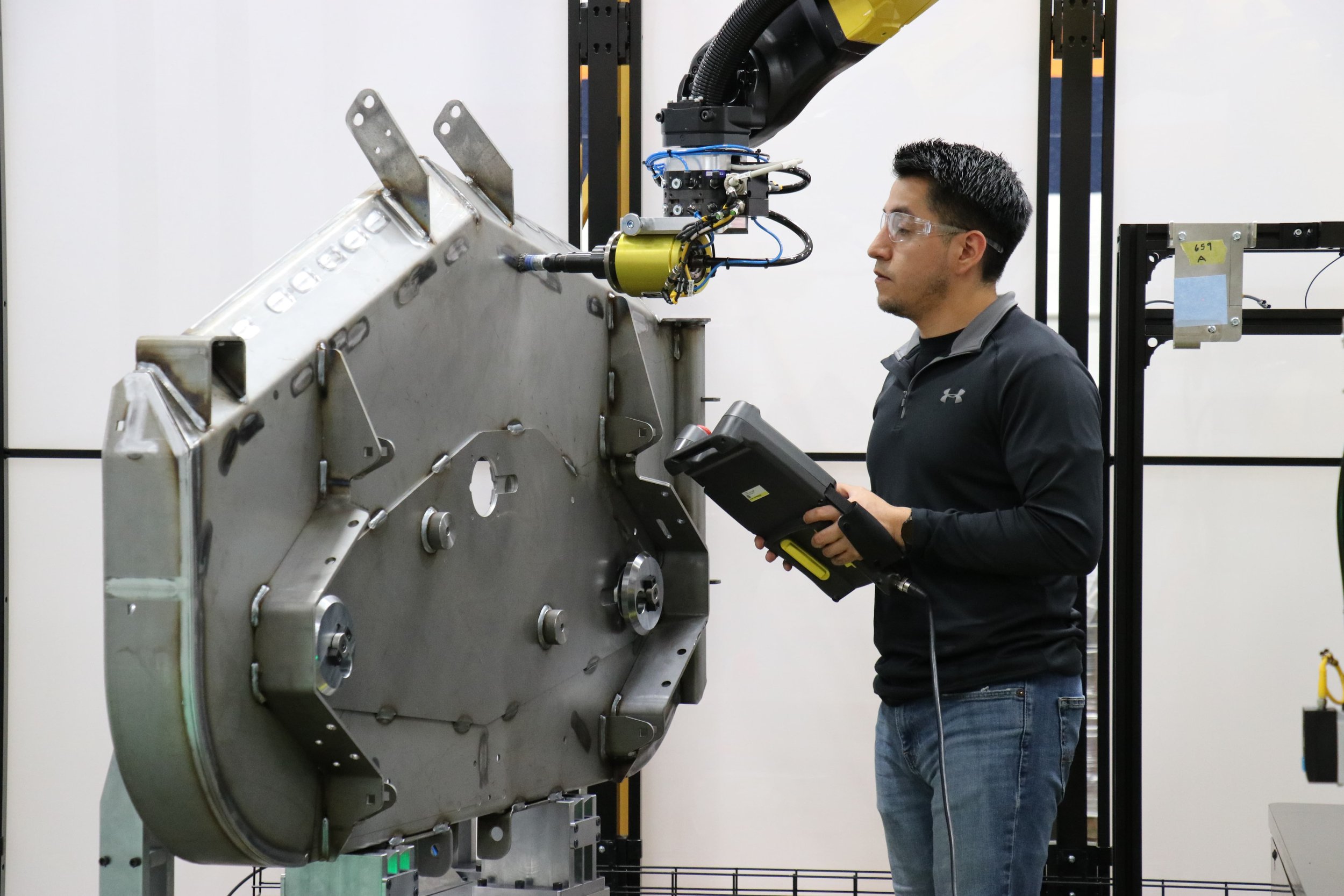

Robotic weld cleaning system - RoboFinisher

Slag removal and cleaning of welds, Deburring after machining, and Rounding of sharp edges is safer, faster, and more consistent with the help of RoboFinisher

Benefits

Increased Operator Safety

Reduce physical strain from dangerous, difficult, and dirty tasks

Reduce repetitive motion injuries

(3) Safety scanner ensure operators are kept out of harm’s way

Increased Quality

Robotic finishing helps to ensure 100% coverage and consistent tool paths every time

Tool wear and compliance monitoring ensures consistent results throughout the life of the wire brush

Increased Productivity

The programmable turntable automatically positions parts for the robot to reduce time and increase throughput

KEY Features

Fanuc M-20iD/25 6-axis Robot with Teach Pendant and Controller

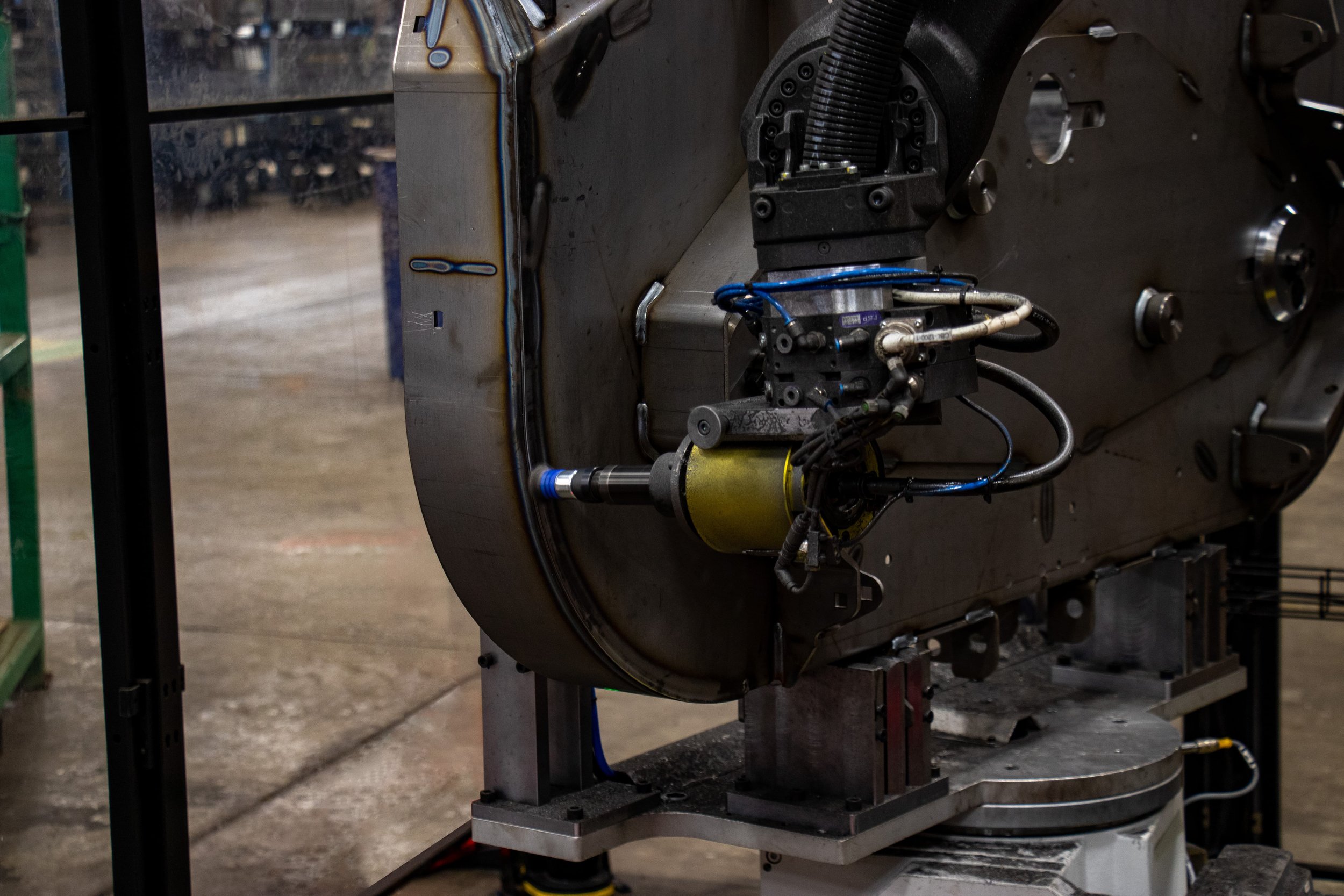

Automatic Tool Changer for End-Of-Arm-Tools (EOAT)

Pneumatic Brushing Spindle with Programmable Axial Compliant Pressure Monitoring

Power: 600 W

Rated speed: 8,000 rpm

Idling speed: 15,000 rpm

Max torque: 3.2/3.6 Nm

Wire Brush Sensor

The wear of the brush is monitored by a sensor and compensated by program control

(2) EOAT Storage Positions

Wire Brush Set-up Station

Servo Indexing Table for Part Positioning

Part Fixtures NOT included

System Controls

Color Touchscreen HMI (Main Screen)

IGNITE A BOLD TRANSFORMATION IN YOUR WORKPLACE WITH AUTOMATED METAL FINISHING

To learn how Metalcraft Automation Group can improve your manufacturing processes, contact us today!